PF / R Method

Concrete placing method based on cast method and non-supporting method when placing the concrete

Method

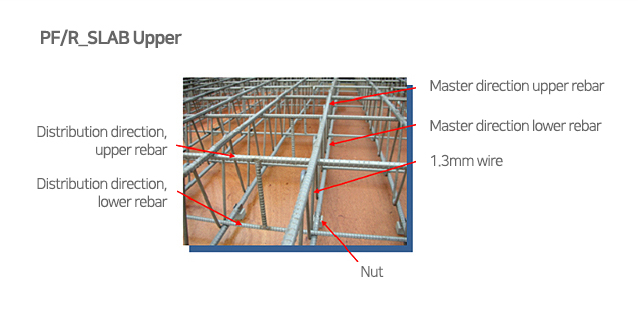

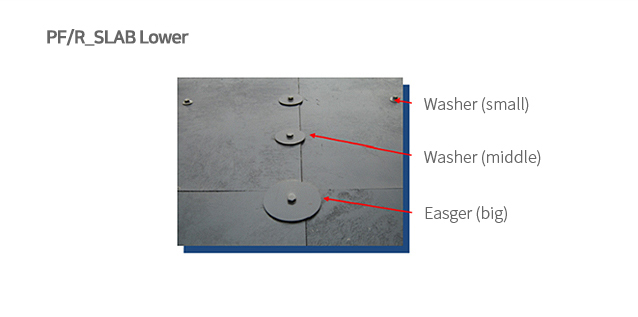

Composed of plywood, bolt(3/8), separator tie, cone nut, wale, Han Chi iron fasteners, horizontal and vertical brass, and main rebar truss. This structure installs PFR form and rebar when placing concrete on site, then installs connecting rebar and clampjoint rebar so that the weight during the placing is supported by the rebar truss and does not use a supporting post. After hardening, the plywood cast can be disassembled to expose the concrete side and the rebar truss supports permanent load

Characteristics and effectiveness of the method

- Characteristics

This method brings the rebar truss of rebar and cast for the slab and wall structure to the site in the state assembled by bolts at the factory to place concrete without the use of temporary structure. This method enables 1. Development of new structural system; 2. Factory automation production; 3. Optimization for application on site; 4. Utilization of disassembled side.

- Effectiveness

Every cast and rebar assembly that would have taken place at construction site is assembled in the factory, thus only the simple installment taking place on site, resulting in cost reduction. Thus, the decrease in number of skilled manpower required from groundbreaking reduction in the amount of labor on site, convenience from decrease in on-site work, and uniform quality can be guaranteed. Also, factory construction unrelated to environmental circumstance can reduce the duration required.

Construction picture - factory production process and installment view

- Material loading

- Lattice bending

- Slab assembly

- Slab completion

- Lifting

- Installment complete